Metalvar New’s solutions to maximize racing cars and motorcycles performances

Exhaust systems consist of a series of pipes, connected to the engine, designed to eliminate exhaust gases. Inside pipes, temperatures reach very high values, suffice it to think that in turbo engines 900 °C can be exceeded.

Heat basically leads to two disadvantages.

The first one is the heating of the engine compartment through irradiation. A poorly thermally insulated exhaust system transmits its heat to all the mechanical and electronic parts nearby located. The main consequences are a general loss of performance, malfunctioning of the electrical parts and, in the worst case, their dissolution.

The second drawback, no less important than the first one, is the slowdown of exhaust gases inside pipes due to heat loss. The more the gases are kept hot, the faster they will be expelled with all the advantages that follow.

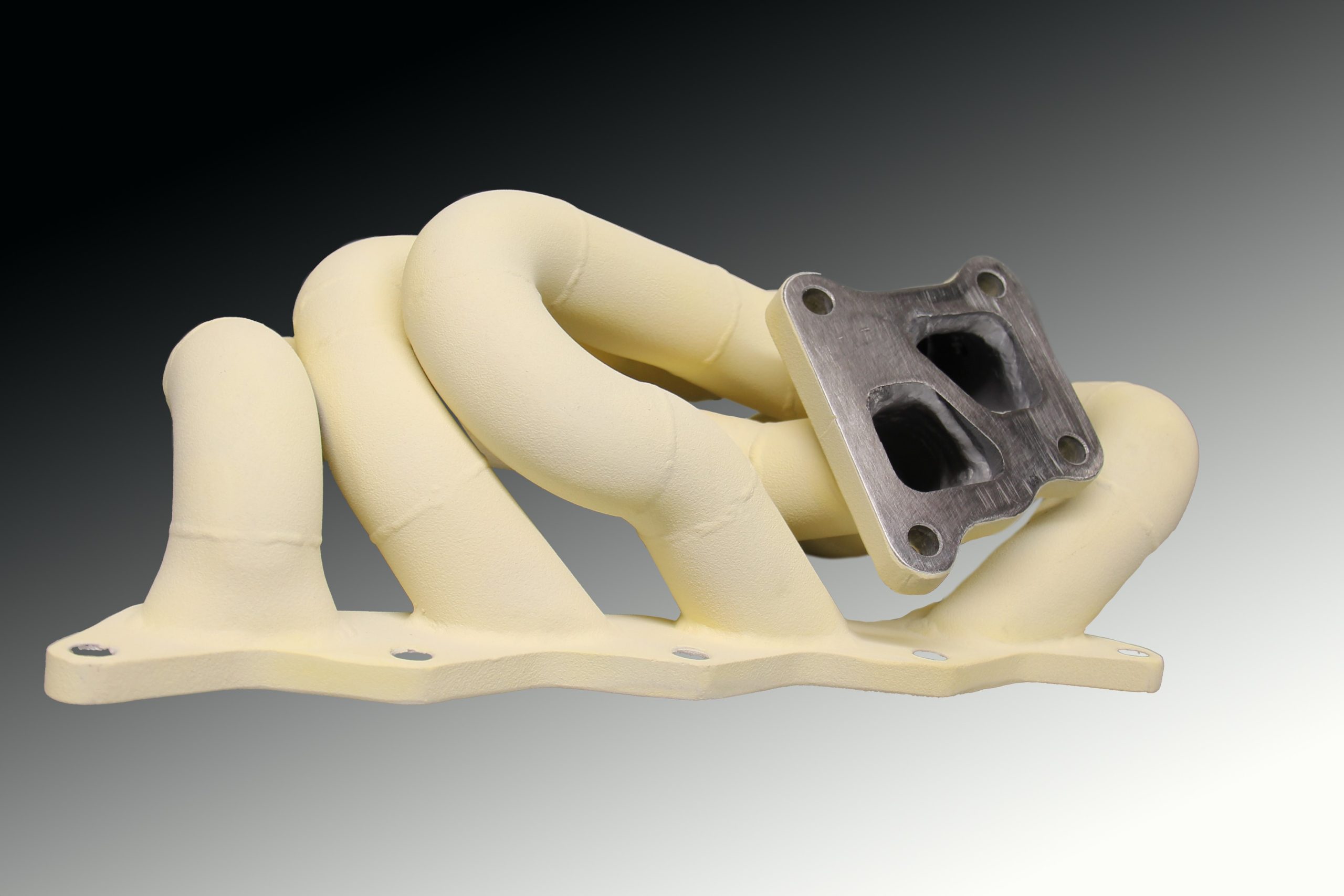

Metalvar New, taking advantage of its knowledge in the energy field, produces ceramic coatings specifically designed to insulate the exhaust manifolds and the turbines of the turbocharger.

The coating used is a powder composed of yttrium stabilized zirconium oxide. This coating has a very low thermal conductivity, therefore it is perfectly suitable as a barrier against heat.

Metalvar New is able to perform this coating on exhaust manifolds of any base material, on the turbine unit and on intercooler pipings.