Metalvar new has been developing metallisation technology for over thirty years.

Would you like to ennoble a mechanic component? Metalvar new has the right solution for your needs.

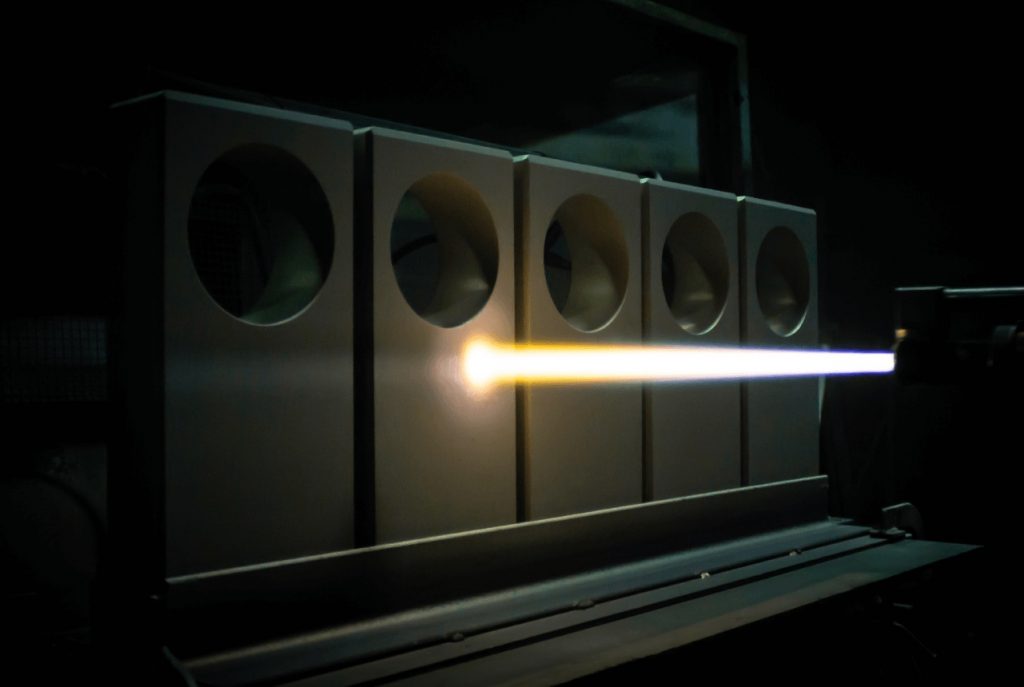

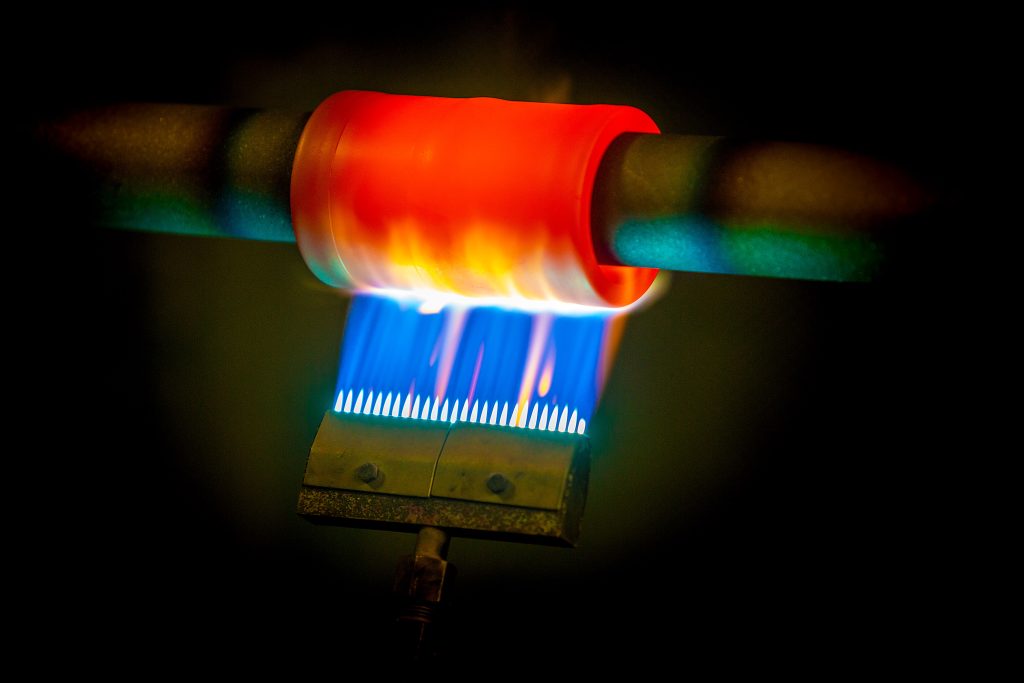

Metallization, better known as thermal spraying, is the cold coating technology in which there is always a flame under different shapes.

Coating materials are usually metals or ceramics in the form of wires or powders.

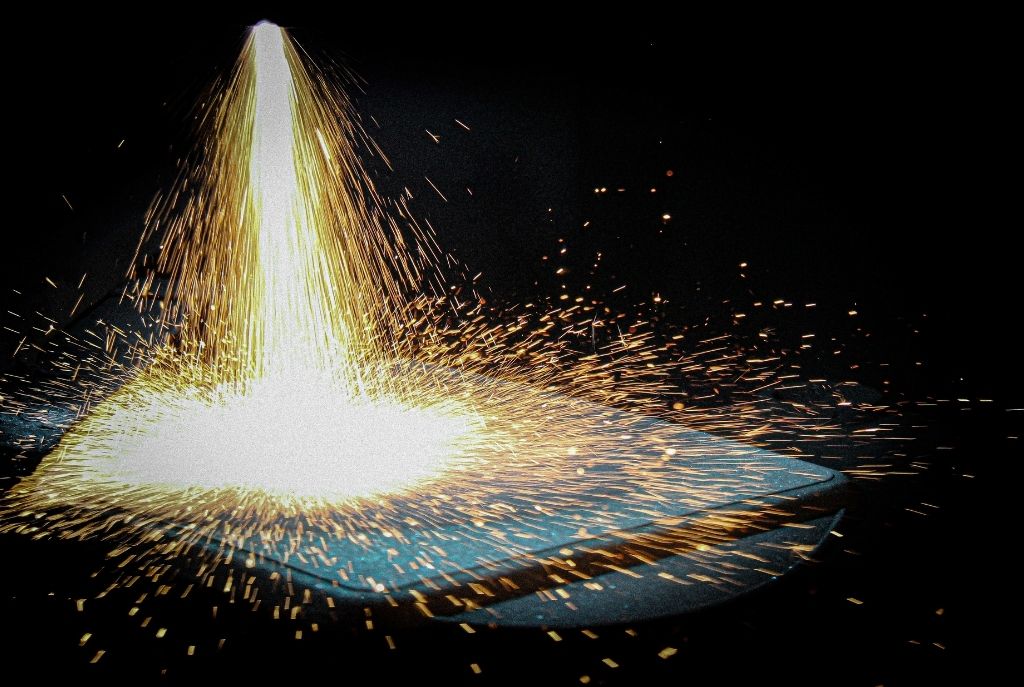

These ones, after being brought to a temperature which is very close to the melting point, are violently projected on to a surface on which coating will form, layer by layer.

Necessary conditions to achieve the metallization process success are the presence of a source of heat or thermal energy combined with a great kinetic energy.

Coating material is submerged into the thermal source where, as well as reaching an advanced plastic state, is subjected to an accelaration given by the combustion energy.

Particles, charged of kinetic energy, violently crash into the component to be coated, fastening to it in a plastic way and loosing instantly all of their heat.

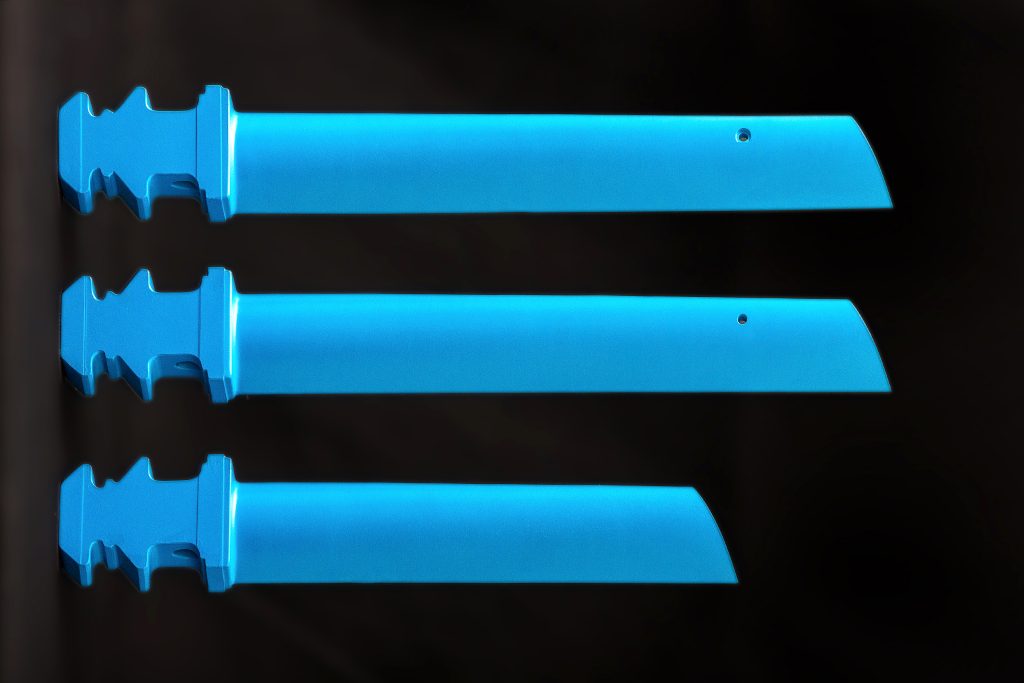

This is exactly the most peculiar feature of thermal spraying. Using this technology it is possible to ennoble a workpiece without warming it, avoiding therefore problems that may be caused by deformation or physical changes of base material.

The wide range of products to which the metallization process is applicable combined to the fact that coatings do not damage the underlayer, allow this application to cover the most varied conditions to which a workpiece can be submitted.