Spray & Fuse

Spray and fused coatings lie outside the classic concept of cold coatings. Coating is initially performed using standard thermal spray processes. Material is brought to a temperature which is very close to the melting point and projected onto the surface to be coated with a high speed.

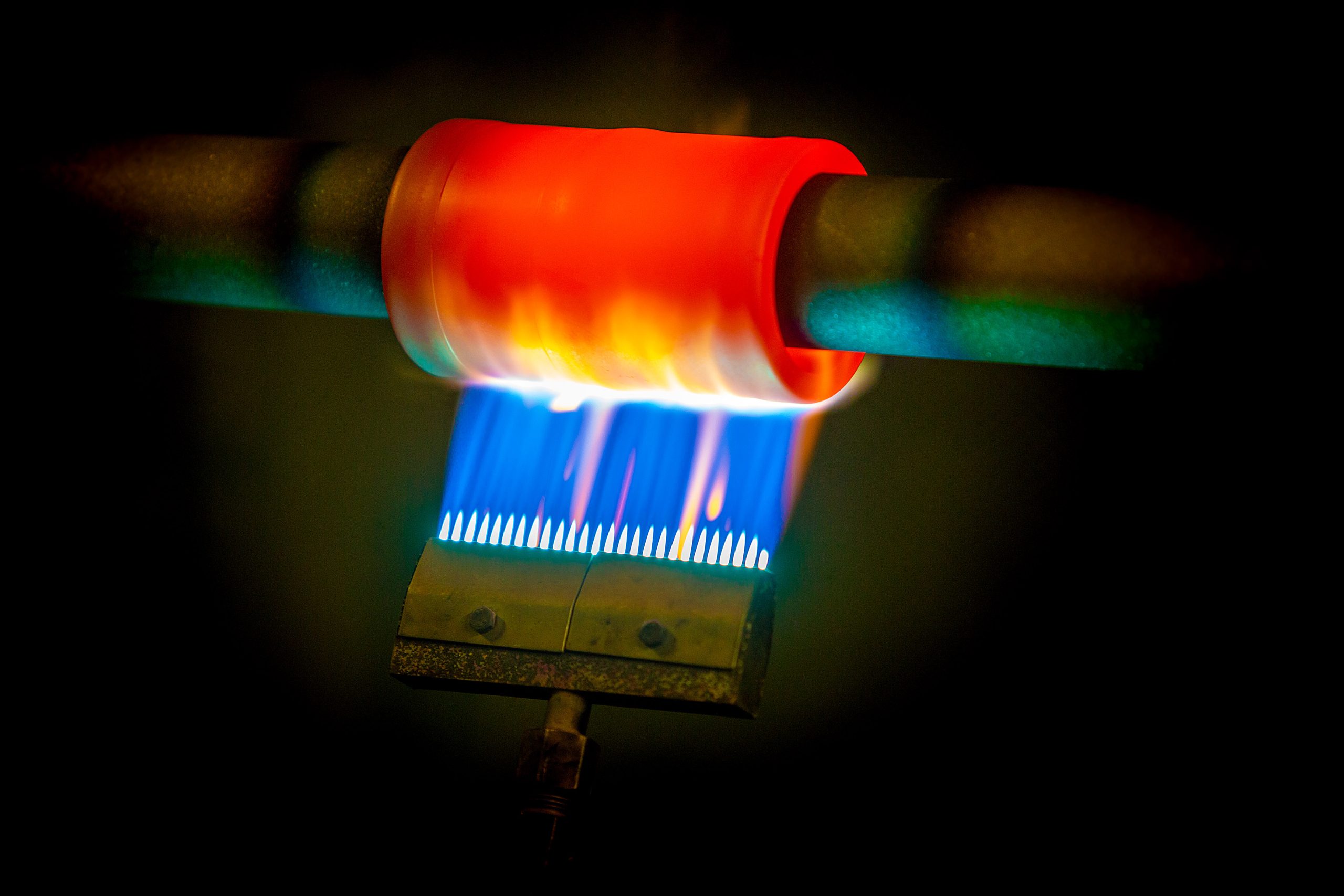

At this moment both the coating and the substratum are taken to high temperatures, usually over 1000 °C, using oxyacetylenic flames, propane gas or special vacuum sealed furnaces at

controlled atmosphere in case of more strict applications.

The result is a thick coating with no porosity and a metallic adhesion to the underlayer showing anchorage values not achievable through classic cold coatings.

To perform this type of coating oxyacetylenic flame, plasma and HVOF systems can be used. HVOF systems are especially employed in aeronautic and mineral sectors.